Unique Wire EDM Materials Machined

Published on: October 14, 2025Titanium Wire EDM

Wire Electrical Discharge Machining (WEDM) is an effective method for cutting titanium. Traditional machining of titanium is challenging due to its poor thermal conductivity and high strength-to-weight ratio. WEDM can achieve exceptional accuracy and excellent surface finishes. It can easily handle intricate geometries, inner corners, and complex contours. Our WEDM machines have AC power generators that eliminate the “bluing” that occurs with older machines having DC power generators. Titanium is a material which is used in the medical field for surgical tools, and other medical devices requiring tight tolerance and high surface finishes. XACT Wire EDM has also mastered titanium applications in the aerospace and automotive industries.

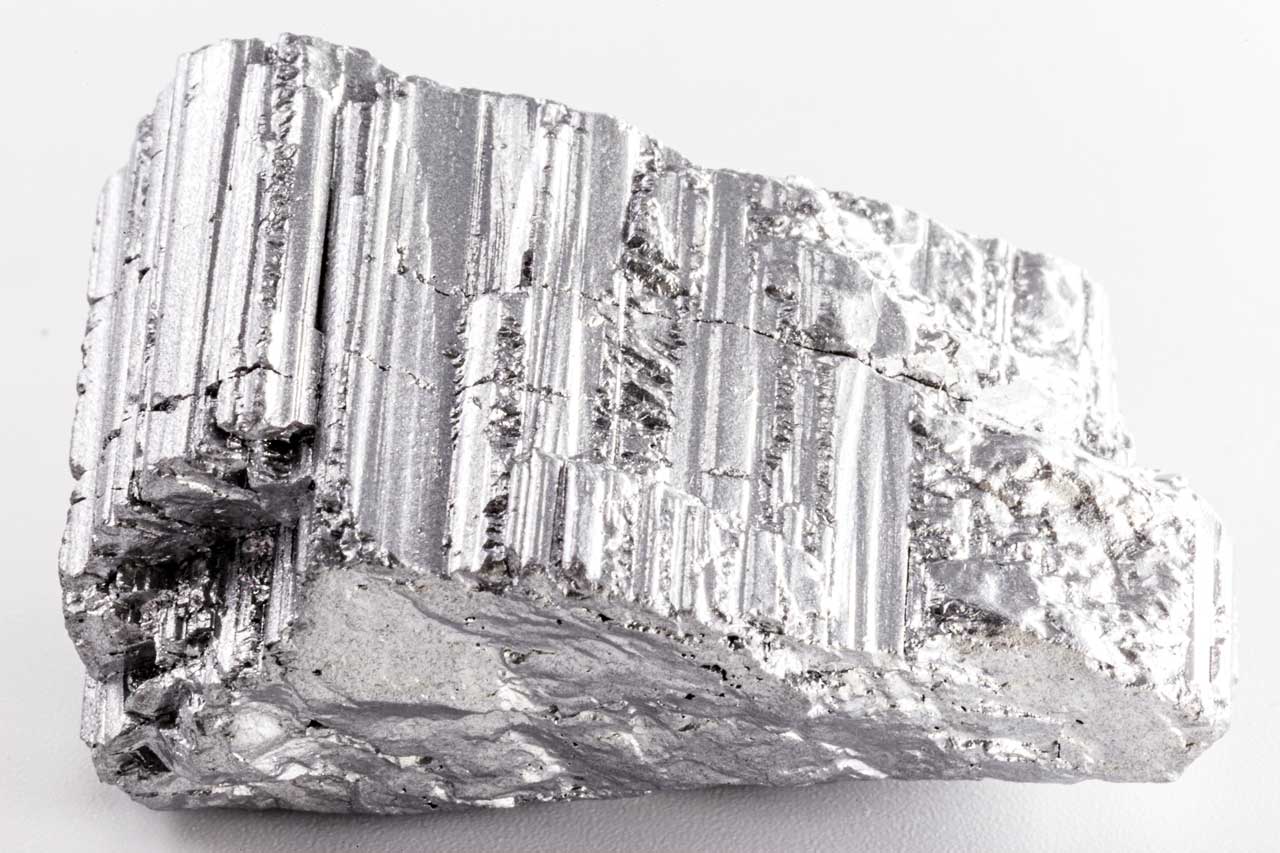

Tungsten Carbide Wire EDM

Wire Electrical Discharge Machining [WEDM] is also an effective and efficient way for machining tungsten and tungsten carbide, which are extremely hard and dense materials. Unlike conventional machining, Wire EDM uses an electrical discharge rather than physical contact which is crucial for tungsten carbide, as it is a brittle material. The Wire EDM process can achieve precision tight tolerances and intricate features. Our modern machines have DC power supplies that are better equipped to prevent micro-cracks. XACT Wire EDM is experienced in machining tungsten and tungsten carbide for the tooling used in the medical, aerospace/defense and automotive industries.

Rare Earth Magnetic Materials Wire EDM

Wire EDM [Electrical Discharge Machining] is well equipped to machine rare earth metals like Neodymium and Alnico which are extremely hard and brittle materials. Since Wire EDM uses no tool pressure, it is perfect for working with intricate shapes and reducing burrs & material distortion. To preserve the magnetic properties of these materials we machine them in their demagnetized state. The parts can then be magnetized afterwards. XACT Wire EDM’s submersed machines are ideal for the cooling and flushing of these materials which is extremely important. We also take careful control of the temperature, magnetic state, and handling of these materials without compromising their properties.

Nitinol Wire EDM

Wire EDM [Electrical Discharge Machining] is an effective, non-contact method for machining Nitinol due to the alloy’s difficulty to machine with traditional methods. Wire EDM allows for complex, miniature features and great tolerance control, as well as repeatability–which is crucial for medical applications and many other applications that require the memory and super elasticity of Nitinol.